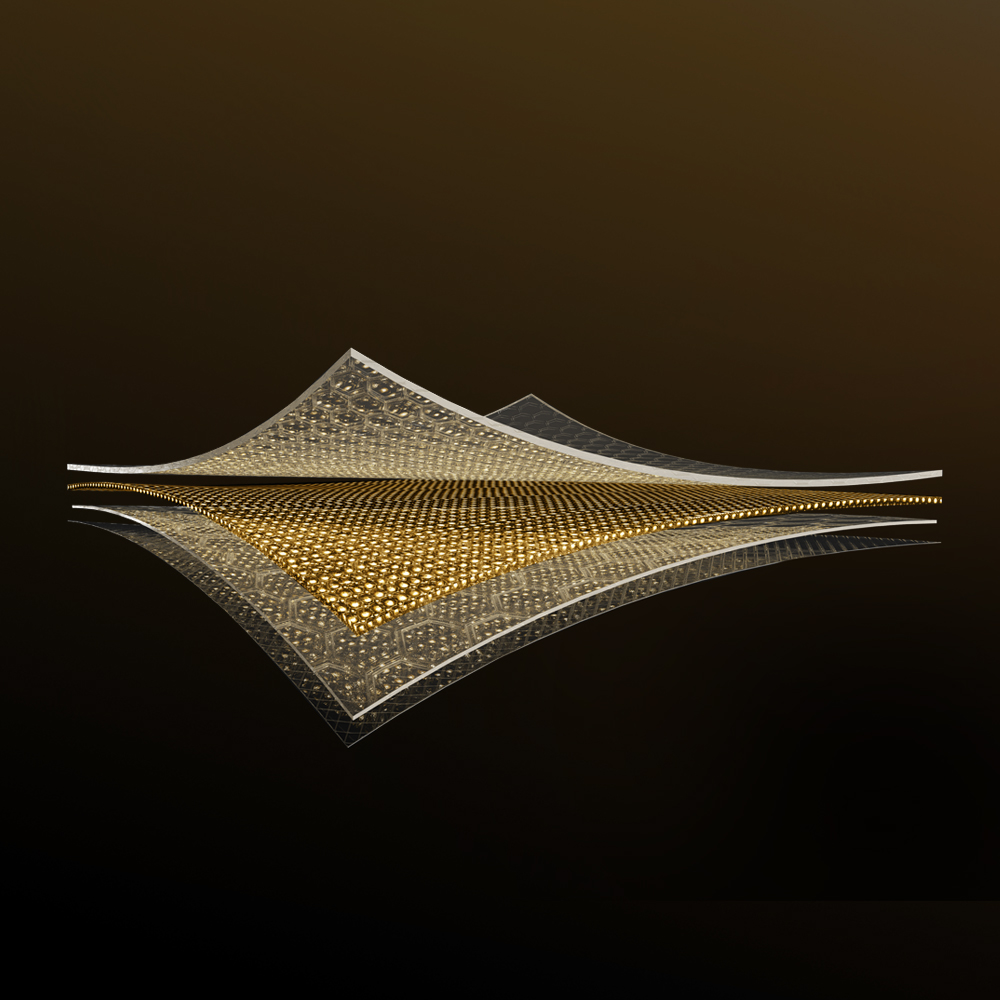

The core of V-KOOL’s infra-red rejection performance is its XIR® Technology, a proprietary high-tech sputtering process developed in Silicon Valley, USA and implemented in Dresden, Germany.

Reflect, not absorb

When compared to conventional window films, V-KOOL’s superior heat rejection performance is obviously felt because dyed and ceramic films absorb infra-red heat and make glass hot whereas V-KOOL Solitaire Series films possess infra-red heat reflection capabilities that help to keep both the glass and interior of your car at a more comfortable temperature.